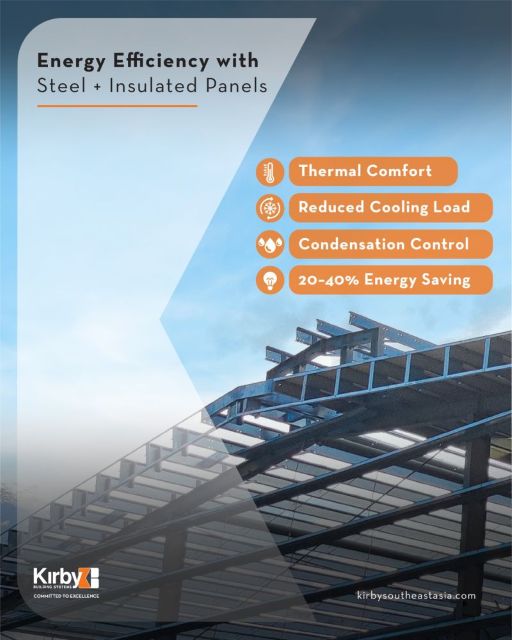

Improving energy efficiency in industrial buildings starts from the envelope – how effectively a structure can control heat transfer between the interior and exterior environments.

One of the most reliable solutions is to combine pre-engineered steel structures with insulated panels from qualified suppliers.

Understanding the concept

Insulated sandwich panels are composed of two steel sheets bonded to an insulating core, typically polyurethane (PU), polyisocyanurate (PIR), or rock wool.

This layered configuration minimizes heat flow through roofs and walls, allowing buildings to maintain a stable internal temperature with less energy for cooling or heating.

Why steel structures make the difference

Steel’s dimensional precision enables panels to be installed tightly, reducing air leakage and thermal bridging – two common causes of energy loss in conventional buildings.

In well-designed facilities, such systems can lower annual energy consumption by approximately 20–40%, depending on insulation thickness, surface color, and building orientation.

Beyond operational savings

Improved thermal performance not only cuts energy bills but also enhances occupant comfort, protects stored goods, and contributes to lower greenhouse gas emissions throughout the building’s lifecycle.

At Kirby Southeast Asia, we design steel building systems that integrate efficiently with a variety of insulation and panel solutions.

Our goal is to help customers achieve higher thermal efficiency and long-term sustainability without compromising functionality or design flexibility.