二次构件/冷弯构件

Secondary structural framing refers to purlins, girts, eave struts, wind bracing, flange bracing, base angles, clips and other miscellaneous structural parts.

Purlins, girts and eave struts are cold formed steel members which have a minimum yield strength of 345 MPa (50,000 psi) and will conform to the physical specifications of ASTM 572 (Grade 50) or ASTM A653 (Grade 50) or equivalent.

PURLINS & GIRTS

Purlins and girts are roll formed Z sections, 200 mm deep with 64 mm flanges shall have a 16 mm stiffening lip formed at 45˚ to the flange. They are supported on columns, rafters or building walls. They can be lapped and nested at the supports which creates a continuous beam configuration. They are placed on the roof and perimeter of the building. Hence they serve as a support to the roof sheeting and wall cladding.

C SECTION

C-Sections are 200 mm deep with a 100 mm flange. The flanges are perpendicular to the web and have a 24 mm stiffening lip.

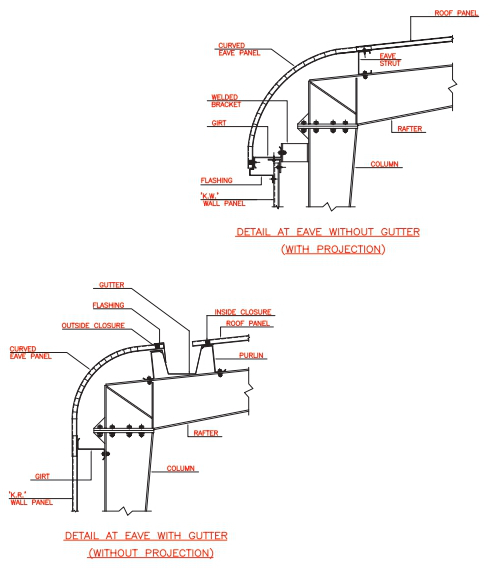

EAVE STRUT

Eave struts are 200 mm deep with a 104 mm wide top flange, a 118 mm wide bottom flange, both are formed parallel to the roof slope. Each flange has a 24 mm stiffener lip. These are located along the sidewall; at the intersection of the planes of the roof and wall. It is constructed from cold formed C-Section and is rolled to suit the roof slope. This member transmits longitudinal wind force on the end walls from roof brace rods to wall brace rods.

OPEN WEB JOISTS

These are long span load carrying trusses suitable for direct support of floors and roof decks in the buildings. The system consists of crimped angles welded to the top and bottom chords.

CURVED EAVES

Curve Eaves can transform the look of any building. Curved canopies and walkways provide an inviting entryway into commercial establishments. Curved eaves eliminate seam lines and provide a smooth line for the eye to follow. Our crimping-curving process increases the rigidity of the curved panels making this choice of panels not only visually appealing but also practically durable.

CROSS BRACING SYSTEMS

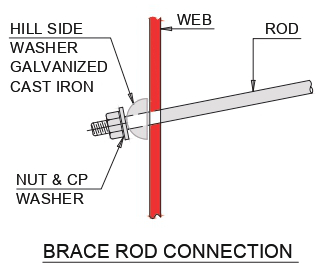

Cable Bracing

Cable bracing is made of extra high strength seven strand cable and can be designed to accommodate any length to ensure the stability of the building against forces in the longitudinal and lateral direction due to wind, cranes and earthquakes. It is made of a cable which is forged into a rod terminal and this arrangement is then fixed on a structure using a hill side washer, nut washer and a nut.

Rod Bracing

Rod bracing shall have a minimum yield strength of 250MPa(36,000 psi) and will conform to the physical specifications of ASTM A-36 or equivalent.

Rod bracing shall have a minimum yield strength of 250MPa(36,000 psi) and will conform to the physical specifications of ASTM A-36 or equivalent.

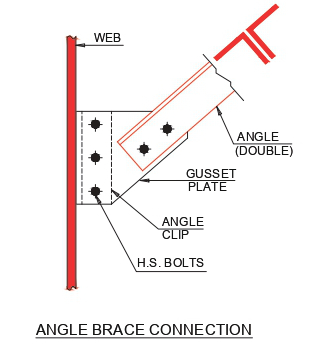

Angle Bracing

Angle Bracings are used to withstand the actions of longitudinal forces ( tension only). These angles shall have minimum yield of 250 Mpa(36,000 psi) or 345 Mpa(50,000 psi)