At Kirby Southeast Asia, one of the key advantages of Pre-Engineered Buildings lies in the use of built-up tapered steel sections – a smarter, more efficient alternative to conventional hot-rolled sections. In PEB design, built-up members are formed by welding steel plates into an I-section whose depth can be varied along the span. This allows engineers to place material exactly where strength is needed, resulting in a lighter yet stronger structure. Why Built-Up Sections Matter Optimized material usage – thicker where the bending

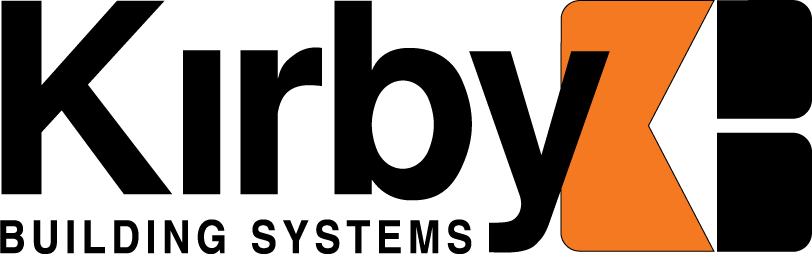

Improving energy efficiency in industrial buildings starts from the envelope – how effectively a structure can control heat transfer between the interior and exterior environments. One of the most reliable solutions is to combine pre-engineered steel structures with insulated panels from qualified suppliers. Understanding the concept Insulated sandwich panels are composed of two steel sheets bonded to an insulating core, typically polyurethane (PU), polyisocyanurate (PIR), or rock wool. This layered configuration minimizes heat flow through roofs and walls, allowing buildings to maintain a stable internal temperature with less

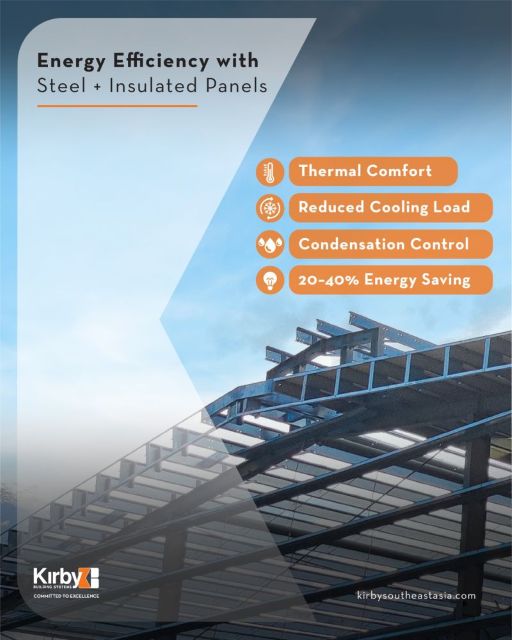

Building smarter also means building cleaner. With steel, we use less water, create less dust, and leave a lighter footprint on the environment. Unlike traditional concrete construction, where water use and dust are part of the process, pre-engineered steel buildings are fabricated off-site and assembled with precision. The result? Cleaner sites Healthier conditions for workers and communities A safer, more sustainable way to grow industries At Kirby Southeast Asia, we believe sustainability isn’t just a feature of the final building, it’s present in every stage

Waste is one of the biggest hidden costs in construction – not just in budget, but in environmental impact. That’s why pre-engineered steel plays such a vital role in sustainable building. At Kirby SEA, every component is precisely fabricated off-site, delivered ready for assembly, and installed with minimal cutting or modification on-site. This process drastically reduces: – Material waste – On-site debris – Rework and errors – Disposal needs Our warehouse project in Thailand is a clear example. Using Kirby’s pre-engineered system, we optimized material usage and minimized waste

In sustainable construction, longevity isn’t the only goal – reusability is the future. That’s why steel stands apart. Unlike concrete or wood, steel is 100% recyclable, infinitely, with no loss in strength. Every beam, column, and truss can be melted down and reborn as part of another building, bridge, or frame. At Kirby SEA, we design and fabricate with this lifecycle in mind – because what we build today should not become tomorrow’s waste. Take our new warehouse project in Negros Occidental, Philippines –

Steel is non-combustible and does not act as a fuel in a fire. That said, like all structural materials, steel’s load-carrying capacity changes when exposed to elevated temperatures. Engineers manage this through design: selecting appropriate sections, limiting loads, and applying passive fire protection so the structure remains stable for the required evacuation and firefighting periods. What makes steel a preferred structural material in fire engineering is its predictable behaviour. Because its response to temperature can be modelled and tested, designers can specify

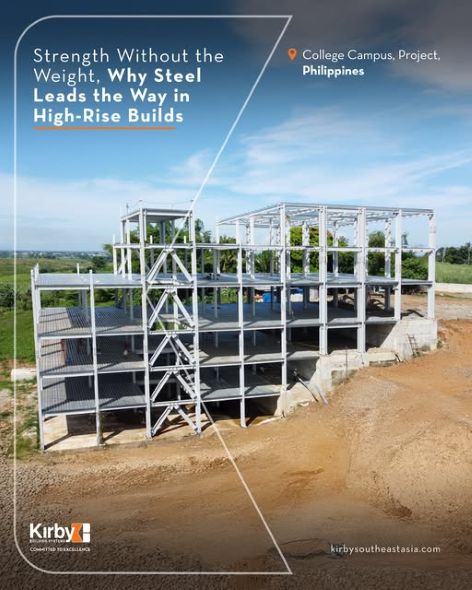

Why steel works for high-rise buildings? Because it’s strong without the weight. That means: • Less load on foundations • Slimmer structures = more usable space • More freedom to go higher, safely It’s this smart balance that makes steel the go-to for towers, commercial hubs, and multi-level facilities. As cities grow upward, steel helps us build smarter. Contact us today: sales@kirby.vn

In high-rise construction, every floor counts — and every day saved matters. That’s why more developers choose steel when speed, safety, and skyline impact are non-negotiable. Kirby SEA is supplying the steel structure solution, allowing the contractor to reach floor targets faster than traditional concrete timelines would allow. Why steel? With off-site fabrication and on-site bolted assembly, steel structures can reduce some projects overall build time by 20–30%. This means: Less labor congestion on-site & Faster vertical progression. For developers, time isn’t just money —

When it comes to complex industrial buildings, accessibility is not an afterthought – it’s a vital part of safety, operations, and long-term performance. At Kirby SEA, we design and fabricate engineered staircase systems tailored for high-rise warehouses and automation facilities. The structure you see here isn’t just a staircase – it’s a precision-built vertical access solution, designed to perform under load, resist lateral forces, and support safe, uninterrupted operation. Engineered in steel. Delivered with certainty. Contact us: sales@kirby.vn